Biofuels, Chemicals, and Energy Stories

Water and Oil

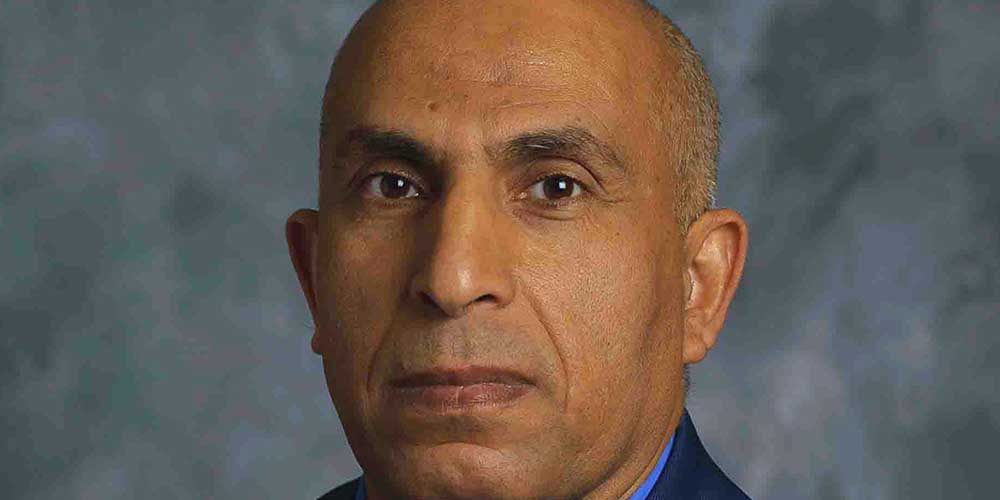

Dr. El Barbary Hassan, a professor at Mississippi State, is collaborating with Mohamed El-Sakhawy from Egypt on a study to convert agricultural waste into renewable biofuels and wastewater treatment adsorbents. Funded by the U.S. Egypt Science and Technology Joint Fund, the study uses rice straw—abundant in both the U.S. and Egypt—to create bio-oil and biochar through pyrolysis. The U.S. team is focused on developing renewable biofuels, while the Egyptian team works on creating low-cost adsorbents for wastewater treatment. This project aims to reduce greenhouse gas emissions from agricultural waste, while producing valuable products for renewable energy and environmental management.

2023

Green is the New Black

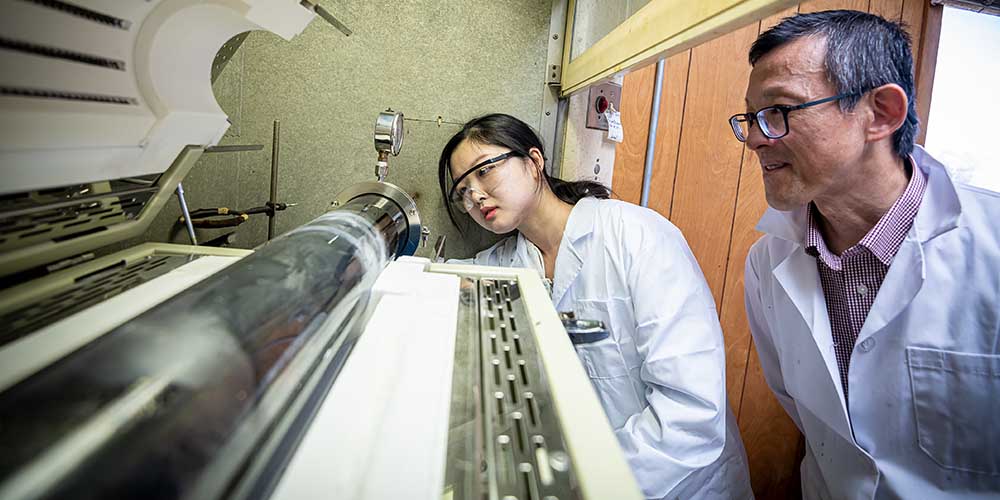

Dr. Jilei Zhang, a scientist at Mississippi State University, is researching the production of lignin-based graphene, a sustainable alternative to traditional graphite. Lignin, a byproduct from paper mills, is typically burned for energy, but Zhang's work explores turning it into bio-graphene oxide, which could have high-value applications. His team has successfully patented methods for producing graphene from lignin, with potential uses in concrete, batteries, and water treatment. Despite challenges in scaling production, Zhang is optimistic about its commercial potential, securing funding to continue research and development, particularly in strengthening concrete and removing heavy metals from water.

2023

FWRC Scientists Explore Natural Materials for Water Purification

Water treatment plants have always used petrochemical-based filters to remove contaminants from public water sources. However, FWRC scientists are now developing water filtration materials from renewable resources. Dr. El Barbary Hassan, professor in the Department of Sustainable Bioproducts, has led this effort, working with MSU colleagues and the USDA Forest Products Laboratory. The team developed gel-based adsorbents from cellulose, which comes from trees, and chitin, which is derived from shrimp exoskeletons. At the time of the study, Hassan said that most water treatment facilities were still using carbon filters but that some were shifting toward adopting hydrogel and aerogel-based filtering methods because these adsorbents are just as effective at removing contaminants as the carbon-based ones.

Hassan has also planned future studies testing the aerogel adsorbents in air filters and masks to remove dust, bacteria, and viruses from the air.